D17 Hydra-Cell High Pressure Coolant Pumps

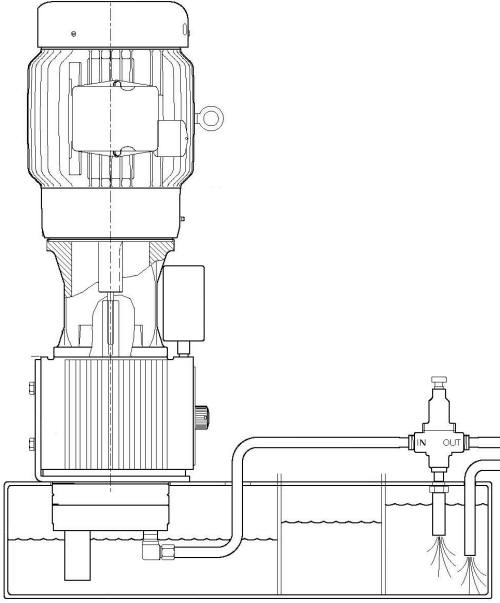

D17 Hydra-Cell high pressure coolant pumps are the vertical version of D15 Hydra-Cell high pressure coolant pumps and thus designed to insert the pump head into your coolant reservoir; sometimes they are mounted vertically to maximize floor space.

Hydra-Cell D17 coolant pumps are used for applications requiring 10 to 15 GPM at pressures 1000>2500 PSI. The installation, operation and maintenance manual (link below) provides critical dimensions and suggestions for coolant reservoir design in support of a smooth running and reliable system.

Although capable of 15 GPM with an 1800 RPM motor, the most common configuration uses a 1200 RPM motor for a flow rate of 10 GPM at pressures from 1000 to 2500 PSI. The pressure regulating valve ensures that the pressure at the tool does not exceed the maximum desired pressure by bypassing any excess coolant back to the reservoir, thus there is no need to control the motor speed.

A significant feature of D17 Hydra-Cell high pressure coolant pumps are their ability to reliably pump reclaimed coolant. Whereas piston, plunger and multistage centrifugal pumps require fine filtration of your coolant, perhaps as fine as 25 microns, the D17 coolant pump only requires a 20 mesh screen (equivalent to a 800 micron filter bag). Therefore other system components, such as your rotary union or tool, dictate the required filtration level. In some cases we can replace your bag filter housing filter bag support basket with a mesh lined version to eliminate filter bag usage altogether!

LOW MAINTENANCE

Maximize manufacturing time with D17 Hydra-cell high pressure coolant pumps as they only require an oil change every 2000 to 4000 hours of operation and check valve replacement every 6000 to 9000+ hours of use. D17 coolant pumps use 2 quarts of standard 10W30 synthetic motor oil and changing the oil is as simple as draining the old oil and pouring in the new oil. Check valve kits cost <$500 and can be installed in under 2 hours; there are no special tools or training required to replace worn check valves. When check valves wear it is noticed by a rougher running pump and inability to maintain a consistent pressure. Unlike other pumps having cups, packing and mechanical seals which leak, there are no fugitive emissions concerns with D17 high pressure coolant pumps.

The photograph above illustrates pump P/N D17EPBGHFECA and pump/motor adapter P/N A04-041-1202; the largest motor for D17 high pressure coolant pumps is 20HP motor, P/N M2000TE12F3P286TCA3, which requires a shaft coupling P/N A04-048-1204 and pressure regulating valve P/N C62ABBVSSEF. Lower horsepower motors might require different adapter and shaft coupling part numbers.

D17 Catalog |

D17 IOM |

D17 Parts |